Copper ore and copper cathode represent two critical stages in the copper production chain, from raw mineral extraction to refined industrial material. This article explores their differences in composition, production, and applications.

Copper ore is a naturally occurring mineral containing copper compounds (e.g., chalcopyrite, malachite) mixed with rock, sulfides, and other impurities. Its copper content typically ranges from 0.5% to 2%, depending on the deposit.

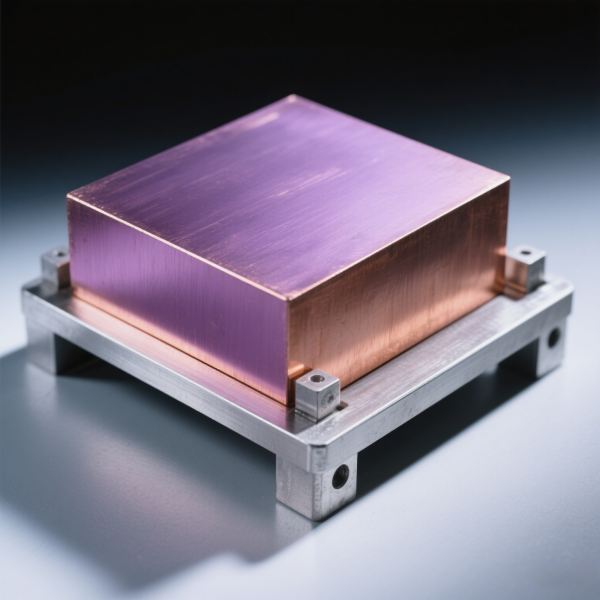

Copper cathode is a 99.99% pure metallic copper product, produced through electrolytic refining. It appears as smooth, thin sheets or plates, ready for industrial use.

| Stage | Copper Ore | Copper Cathode |

|---|---|---|

| Extraction | Mined from open-pit or underground mines. | Derived from smelting and refining copper ore. |

| Processing | Crushed, ground, and concentrated via froth flotation. | Electrolytic refining removes impurities, producing pure copper. |

| Output | Copper concentrate (20–30% Cu). | 99.99% pure copper sheets. |

Primary use: Processed into copper concentrate for smelting.

By-products: Sulfuric acid, precious metals (e.g., gold, silver).

Electrical industry: Wires, cables, and circuit boards due to high conductivity.

Renewable energy: Solar panels, wind turbines, and EV batteries.

Construction: Plumbing, roofing, and HVAC systems.

Copper ore: Mining and processing generate waste rock and emissions but are essential for raw material supply.

Copper cathode: Energy-intensive refining but enables sustainable technologies like green energy systems.

While copper ore is the foundational resource, copper cathode represents the refined end-product driving modern industries. Their differences highlight the transformative journey from mineral to advanced material, underscoring copper’s irreplaceable role in technology and sustainability.