When purchasing anode carbon blocks, buyers are not just comparing specifications—they want to know how quality is controlled at every step of the manufacturing process. In aluminum smelting, consistency and uniformity are critical. Problems such as “anode spikes” or excessive “carbon foam” can severely disrupt the electrolysis process, reduce current efficiency, and increase production costs. That’s why a transparent and reliable quality control system matters.

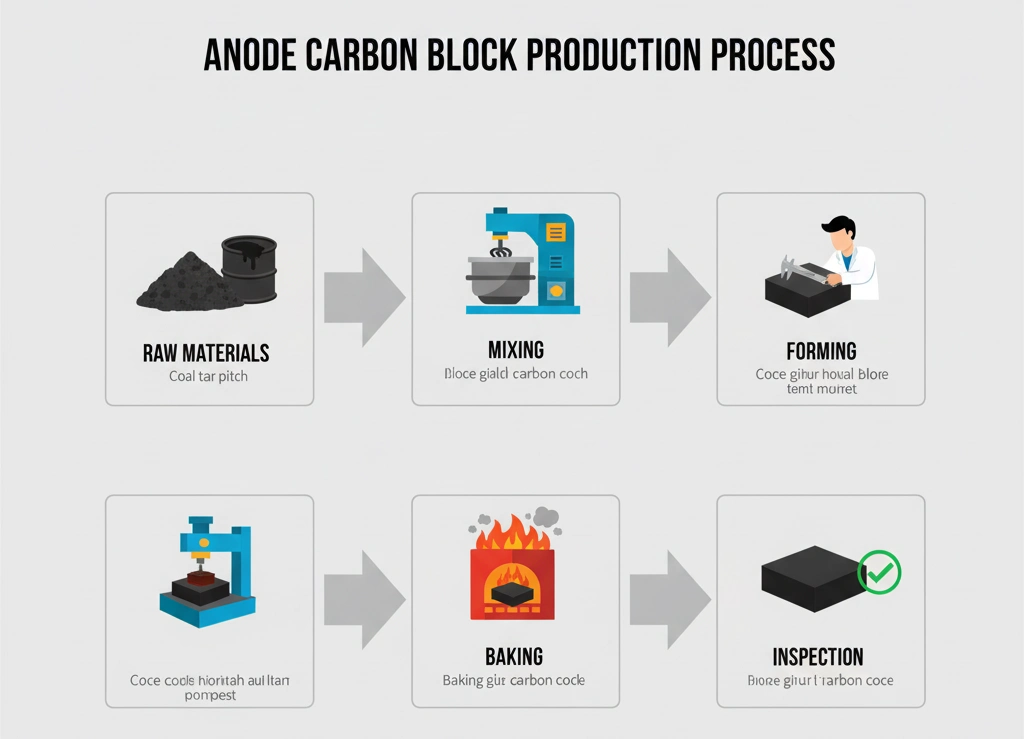

Petroleum Coke: Only high-quality calcined petroleum coke with low ash, low sulfur, and stable particle size is accepted. Each batch is tested for density, sulfur, and volatile content before blending.

Coal Tar Pitch: Used as the binder, it is carefully chosen for its softening point, coking value, and low impurity content. Strict supplier audits and laboratory checks ensure uniformity.

Why it matters: Consistent raw material quality prevents abnormal porosity, weak mechanical strength, and early consumption during electrolysis.

The coke particles are carefully sized and blended to achieve a uniform grain distribution.

Coal tar pitch is heated and precisely added to the mix for optimum binding strength.

Automated mixers guarantee repeatable results and avoid segregation.

Buyer concern addressed: Uniform particle blending reduces the risk of “anode spikes” that cause uneven current distribution.

The mixture is molded under high pressure or extruded into blocks.

Strict control of pressing pressure, temperature, and cycle time ensures each block reaches the required density and strength.

Why it matters: Proper forming minimizes internal cracks and voids that can later turn into carbon foam during smelting.

Blocks are baked in large furnaces at 1100–1200°C to carbonize the pitch and strengthen the structure.

The temperature curve is computer-controlled to avoid thermal stress, which can cause deformation.

Key benefit: Controlled baking guarantees mechanical stability and prevents premature failure in electrolytic cells.

Every batch undergoes rigorous inspection before shipment, including:

Density and porosity measurement

Electrical resistivity testing

Compressive and flexural strength tests

Ash and impurity analysis (Fe, Si, V, Na)

Visual inspection for cracks, voids, and surface defects

Only blocks that meet guaranteed values are approved for delivery. Third-party inspection (SGS, ISO, ASTM) is available upon request.

To ensure long-term consistency, manufacturers adopt:

Statistical process control (SPC) across production lines.

Batch traceability to identify material sources and production conditions.

Customer feedback loops to monitor in-cell performance and adjust parameters.

For aluminum producers, quality control is not optional—it’s the foundation of efficiency and safety. From selecting premium petroleum coke and coal tar pitch, to precision forming and final inspection, every step is designed to deliver uniform, reliable, and defect-free anode carbon blocks.

By minimizing risks like anode spikes and carbon foam, consistent quality helps buyers achieve:

Higher current efficiency

Stable cell operation

Lower power consumption

Longer anode service life

In today's competitive aluminum industry, investing in anode carbon blocks with proven quality control isn’t just a purchasing decision—it’s a strategy for long-term performance.